DC Brushes are prone to one sided wear particular if they are

- Incorrect brushes and springs.

- undersized/ misshaped which causes jamming.

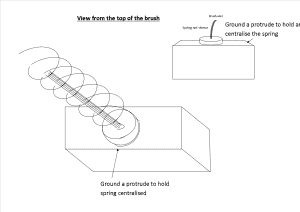

- spring unbiased, Spring is not captive and sitting central to the brush.

- Commutator is worn, wear can cause a dip in the centre of the commutator which must be precisely machined out.

- Over temperature damage can cause springs become brittle and fracture

Diagram shows recessed to ensure the spring is centralised. This extends the wear life by keeping the head of the brush in direct pressured contact with the commutator.