Brushed motors have drawbacks:

Maintenance and cost of replacement brushes

Maintenance and cost of replacement brushes- Wear on the commutator causing degraded performance from ovaling and depression

- Black carbon dust deposits

- At high speed and high torque brushes arc.

- No magnet brake

- poor torque overall

- poor speed control under loading conditions

- consumes more power

- noisy

- heat when in constant use

- When changing to reverse and starting the motor too quickly the main circuit breaker would trip

I took the plunge and finally purchased a 220 Vac 2.2 Kw brush less motor and control unit from AliExpress. I also knew this was not going to be an easy swap upgrade. For info The motor is smaller than the existing and weighs less.

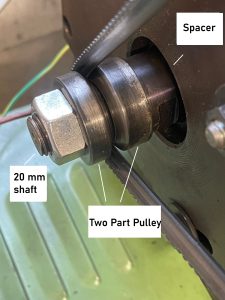

Drive Pulley and spacer

Not a straight swap the fitted pulley had a 15 mm internal diameter with square keyway Locked onto the shaft with a grub screw. the replacement had a 20 mm spindle with 5 mm keyway locked via a M20 nut.

I have since discovered a 15 mm with a square 5mm keyway is available….£40 UKP more expensive….

I manufactured a single pulley wheel, splitting it into two parts, to get the lathe up and running Phot 1 this would ease the cutting of a square key slot recess in the pulleys. A standoff spacer was also needed. view phot 2 to extend the V slot to the correct distance from the motor. In retrospect the pulley needs to be slightly larger in diameter,as it was at the end of its tension setting. I’m now boring out and cutting a key slot into my original pulley , this will offer the higher speed pulley option.

Adaptor Backing Plate

To enable the motor to fit into an existing arrangement for tension adjustment of the Vbelt

To enable the motor to fit into an existing arrangement for tension adjustment of the Vbelt

The plate shown in photo 2 was manufactured from a cheap 6 mm mild steel square,

- a recess was machined out of the plate to accommodate the motor locking in protrusion. Which was not needed as the motor needs to be adjustable for V belts. Phot 3

- M6 counter sunk clearance holes were drilled to bolt the motor to the backing plate, no protrusions from the plate.

- Four holes drilled and partially tapped sized M8, M8 studs were interference fitted into the plate. photo 4

Control Unit / power supply

The cables are far too short for fitting onto a lathe, you need the control panel at the front. For now I’ve left it hanging until I can make up the motor to control unit extended cables. Why this is not offered as an option I don’t know. I’ve ordered the Plugs and sockets. I’ve extended the Pot control wires as I need this on the front to control the lathe. After some research it is advised to keep the drive and Hall sensor cables must nor exceed 330mm maximum to avoid damage to the control unit. ..so extending cables is not an option.

I have decided to extend the speed pot and the reverse button only, once the motor is programmed the other buttons are not used. The pot and the push button Rev switch will ideally be situated where the original pot was located.

Programming: The motor has a built in programming and arrives with default settings. I required the motor to drive anti clockwise on start up, so I searched for the programming guide, this is also not provided on the sellers site. .. I eventually found a guide from a sewing machine which I used to program the motor, not very clear …..

Electrical Brake amongst one of the adjustable parameters I discovered, to my surprise there’s a brake option which I enabled, its an incredible addition speeding up machining operations. No mention of this on the sellers listing … poor knowledge and support of their products.

Observation, When the control unit is powered the motor is magnetized and can’t be manually turned over, this must be consuming power.

Conclusion so far…..,Impressive

- The motor as a whole in operation is an absolute game changer., unfortunately Its in need of major engineering refinements.

- Low speed is accurate and smooth under loading

- The speed response is very quick.

- Not so noisy.

- reverse is also easy, no change over switches to clunk through just push the switch and the motor slows and reverses.

Manual Speed control

The manual speed knob is too course for quick precise speed control, it also has a large zero- speed dead spot , I counted at least 30 plus actual speed increments which are very difficult to select using this Pot. curiously the push button speed control has to be maximized to allow the pot to access the higher speeds, which must be part of the quirky hardware programming. ?? further investigation required.

Things still to do

Short term, getting in running,

- make up some extension cables to enable the control unit to be mounted onto front of the lathe. cancelled….

- Upgrade the mains and the main 3 phase drive cables they all underrated. also cancelled the motor cannot be split down to access the internal connections.

- Measure the current loading in full power..

- The power supply / control unit must be mounted near the motor. therefore, Separate the Speed pot and the forward reverse push button to the front panel.

- Controls need to be integrated into the lathes: start, stop, emergency stop and foot switch stop functions for safety, and unnecessary power consumption.

- Earth connection needs to be attached internally, presently its secured one of the cover screws

Long-term:

-

-

- The existing membrane switches x 4 are just about usable, could be improved with actually quality push button switches and logical separation from each other. …Update only the reverse will be separated and located to the front panel.

- The speed counter is of little use as its the motor speed and not the speed of the spindle, my existing speed counter is defective, not located in the correct position and needs replacement.

-

- I observed a wired in fuse on the PCB this would be a weak point and if needed to be replaced and would be a hassle, I will replace this replace the PCB wired in fuse with an external Circuit breaker. I need to measure the current draw at maximum loading.

For it to be ultimately refined I additionally require a multi push-button fine pre-set speed control with 8 or more pre-set speeds and a manual knob override control. . As access to the rear of my machine is very limited I would prefer manufacturing a new control panel Which would house the majority of the electrical contactors, electronics and also act as a marshaling unit for the machine, Maybe too ambitious …TBC…..

to be continued……